|

Model

|

TB600~2500 sticky note coating machine

|

|

Coating method

|

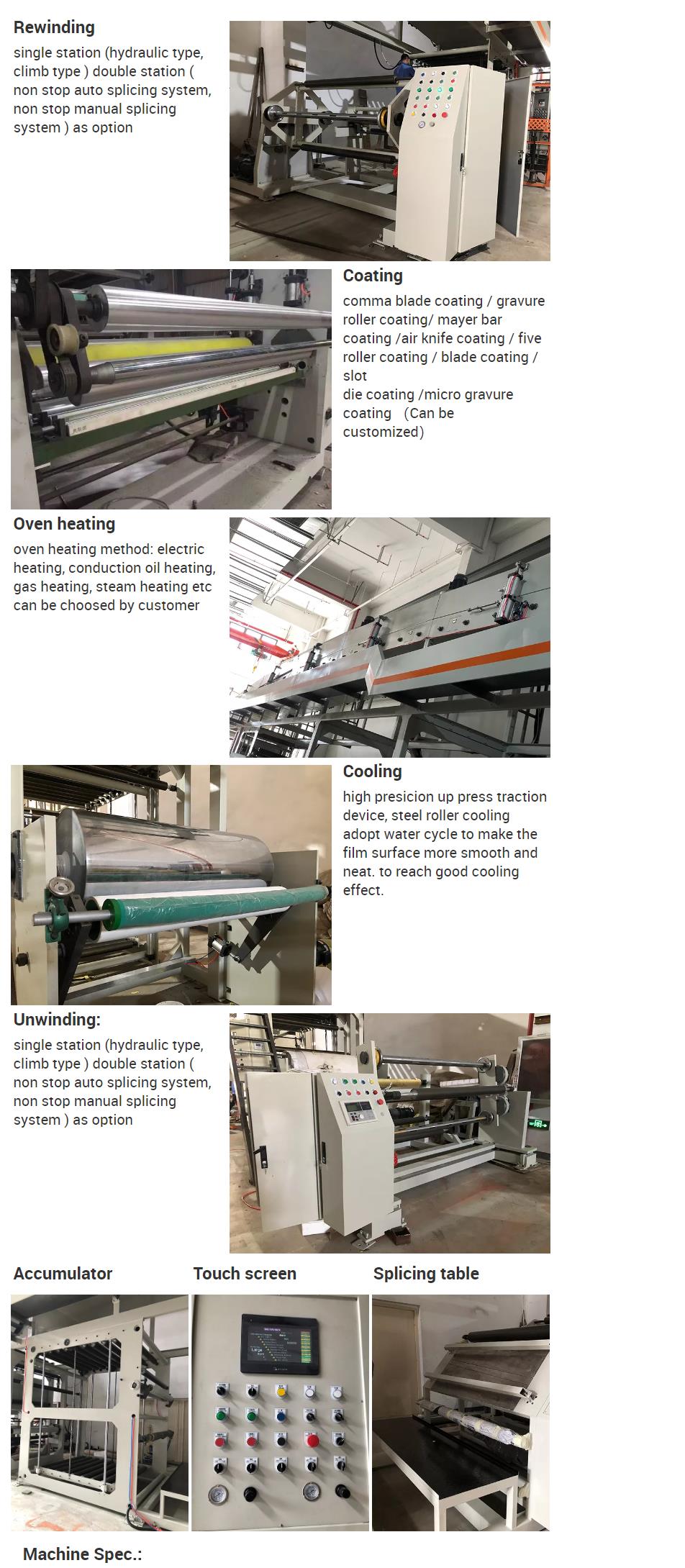

comma blade coating / gravure roller coating/ mayer bar coating /air knife coating / five roller coating / blade coating / slot die coating /micro gravure coating (Can be customized)

|

|

Coating width

|

600-2500MM (Can be customized)

|

|

Unwinding diameter

|

600-1500MM (Can be customized)

|

|

Winding diameter

|

600-1500MM (Can be customized)

|

|

Coating thickness

|

2-300g/square meter

|

|

Coating speed

|

10-300m / min (depending on material)

|

|

Heating method

|

Electric heating, oil heating and natural gas heating

|

* Overall machine adopt 3frequency motor control,

* Electrical rotation double station unwinding frame, adopt magnetic powder auto control the tension

* Gravure coating method, coating blade shaft adopt heavy double shaft type machine independently moving, blade adjust by manual with pneumatic type, angle is adjusted freely, coating quantity is depend the gravure roller mesh, different coating quantity can change different mesh gravure roller.

* For coating more evenness, there is one pc uniformity roller by motor inverter control

* Oven:14m for 6section independently control, heating adopt conduction oil cycle heating, hot air intake type drying system, adjustable inner cycle air intake and out device, air intake and out with strong air , dry thoroughly,

* Oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel so that worker can work very easily.

* The tension between coaitng roller and traction steel roller adopt float swing arm

* Auto-length and speed meter device

* Webguide adopt EPC air sensitive register to assure the trimness when rewinding

* Rewinding and unwinding adopt key type airshaft for easily operate when loading and unloading the material

* High presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat. to reach good cooling effect.

* Rewinding frame is alongside rewinding, the drive same as traction unit

* Electrical rotation double station unwinding frame, adopt magnetic powder auto control the tension

* Gravure coating method, coating blade shaft adopt heavy double shaft type machine independently moving, blade adjust by manual with pneumatic type, angle is adjusted freely, coating quantity is depend the gravure roller mesh, different coating quantity can change different mesh gravure roller.

* For coating more evenness, there is one pc uniformity roller by motor inverter control

* Oven:14m for 6section independently control, heating adopt conduction oil cycle heating, hot air intake type drying system, adjustable inner cycle air intake and out device, air intake and out with strong air , dry thoroughly,

* Oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel so that worker can work very easily.

* The tension between coaitng roller and traction steel roller adopt float swing arm

* Auto-length and speed meter device

* Webguide adopt EPC air sensitive register to assure the trimness when rewinding

* Rewinding and unwinding adopt key type airshaft for easily operate when loading and unloading the material

* High presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat. to reach good cooling effect.

* Rewinding frame is alongside rewinding, the drive same as traction unit