|

Model

|

TB600-2500 double side wax coating machine

|

|

Coating method

|

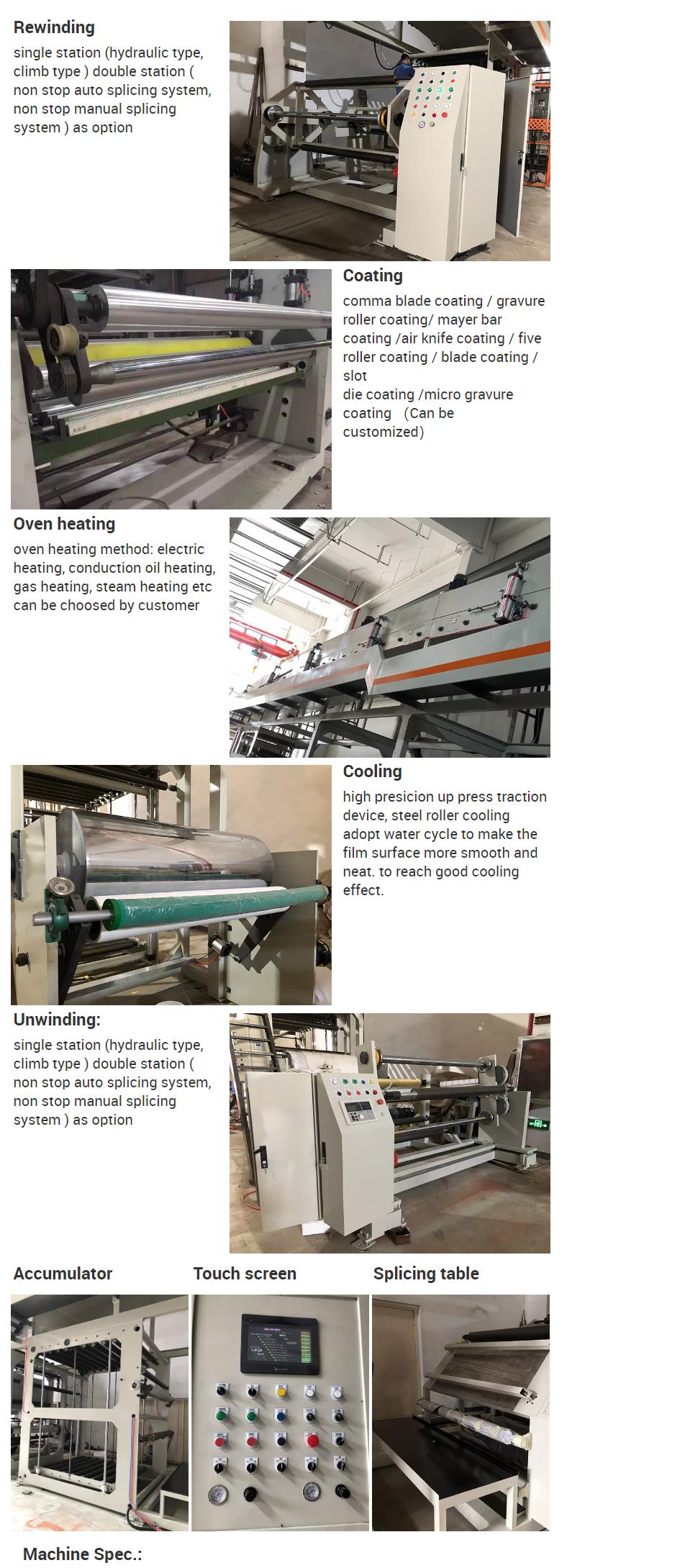

comma blade coating / gravure roller coating/ mayer bar coating /air knife coating / five roller coating / blade coating / slot die coating /micro gravure coating (Can be customized)

|

|

Coating width

|

600-2500MM (Can be customized)

|

|

Unwinding diameter

|

600-1500MM (Can be customized)

|

|

Winding diameter

|

600-1500MM (Can be customized)

|

|

Coating thickness

|

2-300g/square meter

|

|

Coating speed

|

10-300m / min (depending on material)

|

|

Heating method

|

Electric heating, oil heating and natural gas heating

|

1. The whole machine is controlled by 3 variable frequency motor.

2. The discharge rack is in the form of single station and adopts magnetic powder automatic tension control.

3. Anilox coating method. The coating amount depends on the mesh line of the anilox roller. The anilox roller with different mesh line can be changed for different coating amount.

4. The intermediate tension between the coating roller and the traction steel roller is synchronously controlled by floating swing arm

5. Automatic meter and speed control device

6. EPC edging machine is used for deviation correction to ensure the tidiness of material winding.

7. The retracting and releasing shaft adopts key type inflatable shaft for convenient loading and unloading operation.

8. High precision up pressing traction device. The cooling of steel roller adopts water circulation type. Through the cooling roller, the film is smoother, scratched more and achieves the cooling effect.

9. The form of receiving rack is single station, and the winding is controlled by frequency conversion motor and vector frequency converter.