|

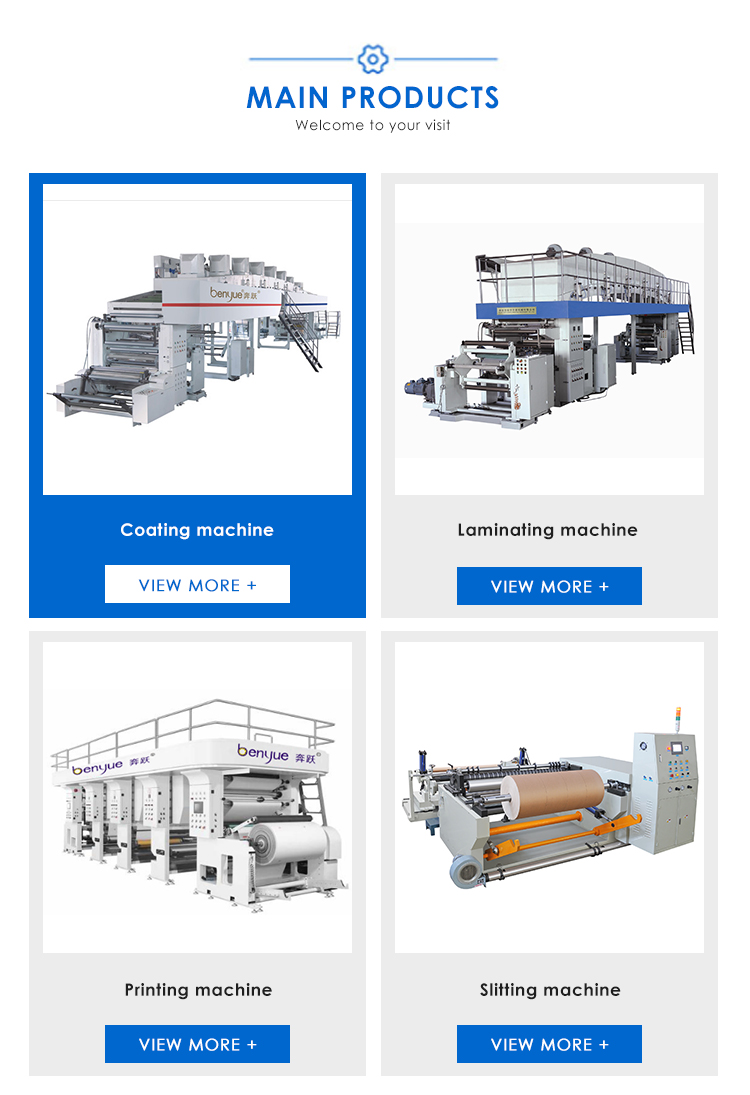

Model

|

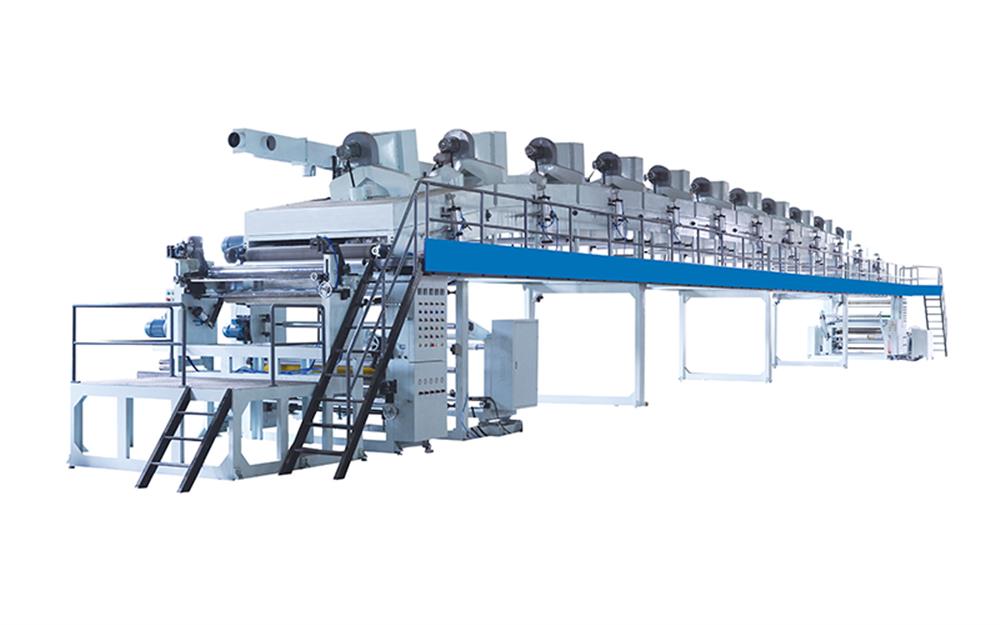

TB600-2500 solventless silicone oil coating machine

|

|

Coating method

|

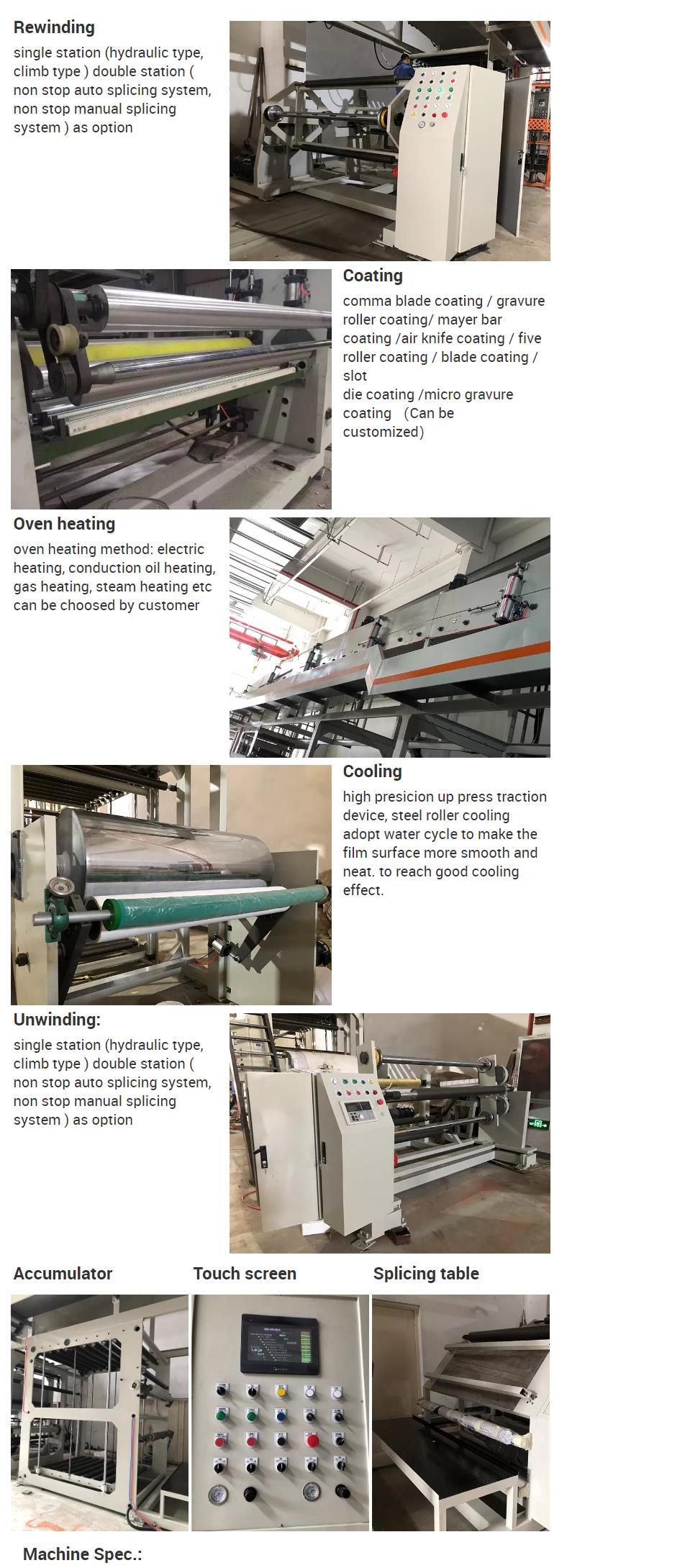

comma blade coating / gravure roller coating/ mayer bar coating /air knife coating / five roller coating / blade coating / slot die coating /micro gravure coating (Can be customized)

|

|

Coating width

|

600-2500MM (Can be customized)

|

|

Unwinding diameter

|

600-1500MM (Can be customized)

|

|

Winding diameter

|

600-1500MM (Can be customized)

|

|

Coating thickness

|

2-300g/square meter

|

|

Coating speed

|

10-300m / min (depending on material)

|

|

Heating method

|

Electric heating, oil heating and natural gas heating

|

1. The whole machine is controlled by 4 frequency conversion motor, and the whole machine adopts automatic tension control, and the speed is kept in sync

2. The discharging frame is independent and adopts magnetic particle automatic tension control.

3. The pattern coating method, the coated scraper shaft adopts heavy-duty double axis machine to swim independently. The scraper adjustment mode is manual pneumatic type, and the angle is adjusted arbitrarily. The coating amount depends on the mesh of the mesh roller. Different coating amount can be changed for different mesh roller.

4. The oven is 10 meters divided into 4 sections for independent temperature control. The electric heating hot air enters the drying system. The heating box is external, and the heating pipe is made of stainless steel with heat sink. The adjustable internal circulation suction and exhaust device is adjustable. The wind force of the air inlet and exhaust is strong and the drying is complete.

5. The guide wheel in the oven is synchronized with the main engine actively, and the synchronous belt wheel transmission is adopted for transmission, which reduces the material tension and deformation. The cylinder open top oven and the membrane penetrating operation platform make the operator easy to work.

6. The floating swing arm type automatic tension control is adopted for the tension synchronization between coating roll and traction steel roll

7. Automatic meter speed control device;

8. EPC gas sensitive edge machine is adopted for rectifying deviation, so as to keep the materials in order to be rolled.

9. The key type air expansion shaft is used for the storage and release, so that the handling of materials is convenient.

10. high precision upper pressure traction device, the steel roller cooling adopts water circulation type, and makes the film more flat, more scraped and more cooling effect through the cooling roller.